Novecal: custom synthesis through innovative catalysts

As industries seek to reduce their carbon and environmental footprints, Novecal is offering innovative products and services, particularly in the field of catalysis.

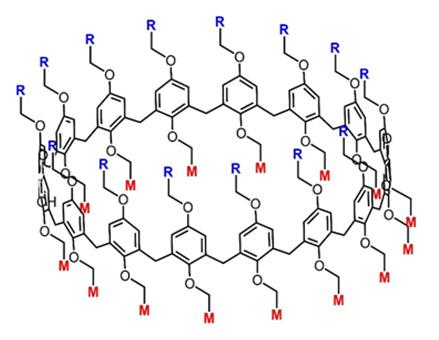

The story of Novecal began in 2010, when Cyril Martini, then a post-doctoral fellow in chemistry, joined the team of researcher Vincent Huc, specialising in molecular chemistry at the Molecular Chemistry and Materials Institute of Orsay (ICMMO - Univ. Paris-Saclay/National Centre for Scientific Research, CNRS). " During our research, we discovered the existence of giant calixarenes, cyclic oligomers that can reach several nanometers in size. Following this discovery, we developed our first catalysts using calixarenes as a support, in an academic context," explains Cyril Martini, President of Novecal.

Their work was funded through innovation competitions, and from 2015, the researchers undertook a two-year maturation project with SATT Paris-Saclay. Several patents were subsequently filed, including one in the field of catalysis. In 2017, Cyril Martini won the i-Lab competition run by the French Ministry of Higher Education, Research and Innovation, securing a €225,000 grant. His project was then incubated at IncubAlliance.

It was against this backdrop that he founded the start-up Novecal in 2018, together with Emmanuelle Schulz and Vincent Huc. The company was initially hosted at ICMMO, before moving to one of the buildings on the Orsay campus in June 2022. In 2021, the start-up won the "Companies Committed to Ecological Transition" award from French Environment and Energy Management Agency (Ademe). Today, Novecal has a team of three researchers and one operational trainee.

Developing catalysts

Novecal's main activity is the design, research, development and production of catalysts. Calixarenes are cyclic molecules typically composed of four to eight repeating units. For example, they are used to trap radioactive elements or encapsulate organic molecules. " We had the idea of using giant calixarenes as a support to generate catalysts. This aimed to minimise contamination of intermediates and active pharmaceutical ingredients by the metals found in the catalysts. Ultimately, the concept worked with a smaller calixarene that was easier to produce. The catalysts, generally palladium-based, are integrated into each unit of the calixarene," explains the President of Novecal.

The main advantage of this type of catalyst is that it can be designed in a homogeneous phase but used in heterogeneous catalysis, depending on the choice of solvent. This offers several benefits: reproducible performance, the ability to recover the metal through simple filtration and a significant reduction in contamination of intermediates and finished products. This allows for the recycling of rare metals and simplifies the chemical reaction on an industrial scale.

Novecal has already created several generations of these innovative catalysts, which are available in a catalogue or through distributors across the European Union. While the pharmaceutical industry accounts for the majority of Novecal's customers, Cyril Martini notes that " catalysts can be difficult to sell, as pharmaceutical companies are very cautious about working with small companies like ours due to concerns about supply reliability." He adds: " The value of our products should not only be measured by the effectiveness/price ratio. Our products are more expensive, but they allow savings throughout the manufacturing cycle, by reducing the use of solvents, the number of analyses, labour costs, and by freeing up production tools. These are elements that are difficult to convey to investors and pharmaceutical R&D executives." »

Several projects in parallel

Despite its small size, Novecal is always busy with several projects at once. The company is currently working with a major company in the chemical industry to develop a catalyst for manufacturing commodity products. " While the added value is low in this market, the volumes are very high. Our innovation has been tested and approved, and it works very well. The catalyst is recycled in a loop and does not clog the reactor, which has interesting environmental and economic implications. A new patent will soon be filed," Cyril Martini says proudly. If successful, the project could generate between 0.5% and 2% of the gross sales generated by the partner.

The young company is also embarking on a project to develop homogeneous catalysts in collaboration with Université Paris-Saclay and the CNRS. " Here, we are tackling what are known as C-H (carbon-hydrogen) activation reactions. The aim is to shorten the synthesis stages of active pharmaceutical and agrochemical ingredients. Instead of using intermediates with halogen functions or metal derivatives, we can carry out coupling reactions directly from the precursors. The economic and environmental stakes are significant for the industry and the initial results are very encouraging ," adds the President of Novecal. Novecal is still in its early stages, but the first homogeneous catalysts produced have already reduced the amount of catalyst used in C-C (carbon-carbon) or C-N (carbon-nitrogen) coupling reactions by a factor of 100.

Bespoke research and development

In addition to its work in catalyst design, synthesis, development, production and sales, Novecal also offers research and development services. These services aim to solve industrial problems, assist with scaling-up processes, and develop tailored syntheses, including total syntheses of active ingredients. " For example, we optimise catalysis reactions by testing catalysts under different conditions, modifying the solvent, temperature, base, etc.," explains Cyril Martini. To achieve this, the team is equipped with a wide range of equipment: rotary evaporators, including an industrial machine with a 20-litre capacity and temperature-controlled reactors of a similar volume.

In a previous project, Novecal developed technology based on an oil able to modify the viscosity of formulations through simple heat treatment. This technology is now used on a large scale in the materials industry.

Novecal has also recently completed another project for an Indian company. " The task was to perform the total synthesis of a natural compound. We started from scratch to chart out the synthesis pathway. It took us four months, which is a remarkable achievement in terms of speed," says the start-up's President.

Currently, the young company is focused on a project with a major French company looking to improve a catalysis stage. " This is an enzymatic catalysis process that requires a signifiant amount of water and takes nearly four weeks. Our aim is to reduce this stage to just a few hours by using more conventional catalysts," explains Cyril Martini. He continues: " It's still difficult to make a name for ourselves in the field and to find customers. Our sales and marketing strength is very limited. But it's always a source of pride when we manage to create products or deliver services that have tangible societal impacts." »